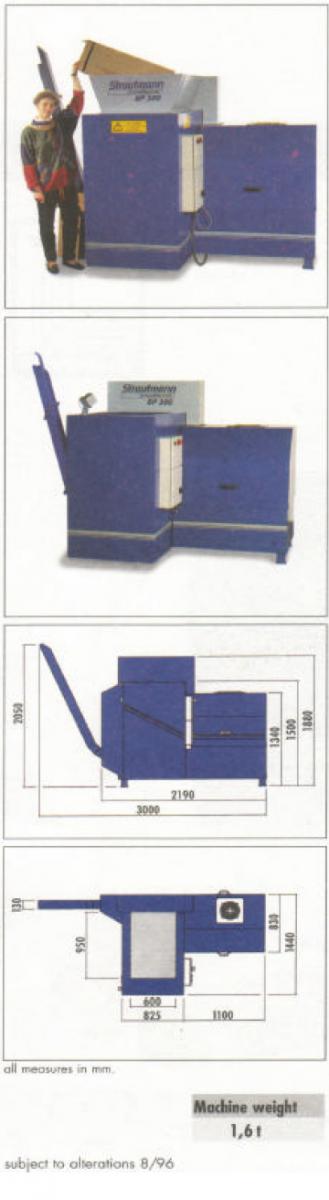

RECYCLABLES COMPACTOR

On Site Recycling System

Fully automated compaction system for recycling of waste products and production of briquettes as a commercial product, or as a general waste reduction device for industries burdened with large volumes of waste. The safety features of the recyclables compactor comply with high European safety standards. Recyclables such as cardboard, paper, sawdust, plastics, styrofoam, and aluminium and steel cans are easily loaded into the hopper of the recyclables compactor. The two stage continuous feed compacting process releases the briquettes from the chute on the side of the unit. Two microprocessor controlled consoles make it easy to operate, record hours of operation and monitor oil pressure and temperature

Aerobic cell of the FABCOM® system

Aerobic cell of the FABCOM® system

FEATURES

- Volume is reduced by 95%

- Simple to use, easy to operate

- Versatile and efficient

- Compact and robust

- Easy installation

- Occupies only 3 m2 of space

- Hydraulic pressure 25 t

- Processes up to 300 kg/hr

- Microprocessor operation

- Hopper capacity 0.8 m3

- Continuous feed

Aerobic cell of the FABCOM® system

Aerobic cell of the FABCOM® system

TECHNICAL SPECIFICATIONS

- Dimensions 3m x 3m x 2m ( L x W x H )

- Weight 1.6 tonne

- Power 400 V 7.5 kW 50 HZ

- Noise level 75dB

- Large hopper opening 950 x 600mm

- Briquettes 80 x 80x 100-300mm

- Larger compactors are available

BENEFITS

- On site recycling system

- Minimises transport costs

- Turns paper and cardboard into fuel briquettes

- Plastics ( incl. Styrofoam ) and aluminium become stackable briquettes

- Applications in mining, shipping, industry, remote communities, country towns, etc

Aerobic cell of the FABCOM® system

Aerobic cell of the FABCOM® system

Fully automatic compression system

-after filling hopper with waste material the pre-compression of material will start automatically

-the compressed briquettes will be pushed continuously through the discharge channel and can be removed by means of any container

Volume Reduction up to 95%

-high press power: 25kN

-high surface pressure 390 kg/qcm

Bulk weight up to 600 kg/m3

-high press power: 250 kN (ca. 25 t press weight)

-briquetting achieved without the addition of any other substance

High capacity throughput

-in the case of carton/paper up to 300 kg/h

Continuous feeding

-loading of material during briquetting

-suction feeding is possible in combination with automatic start

Operator friendly

-micro processor control

-easy loading

-low noise under 75dB

Large loading aperture

-generous loading inlet (950 x 800mm) facilitates ease of material loading

Large chamber capacity

-large loading chamber : 0.8 m3

High safety standards

-complies to German Standards

Easily installed

-compact design

-small floor area requirement, under 3m2

-low machine height

Optional accessories

-automatic start light beam

-feed hopper up to 2m3 material input

-galvani sed finish for wet environment

-collection containers

-shredder equipment

Press weight

25 tonne

max. Briquette dim.

80x80x100-300mm

Briquette density

1m3 up to 600kg